When to Choose Propane vs. Electric Concrete Cutting Tools

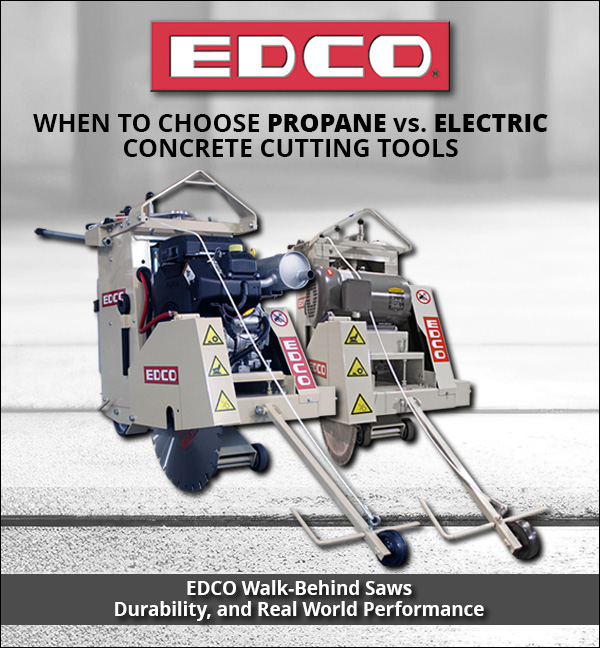

Concrete cutting isn’t one-size-fits-all. Jobsite conditions, safety rules, and productivity needs all play a role in which saw you should put on the slab. EDCO builds propane and electric options to give contractors and rental centers the flexibility they need, with features that set them apart in durability, serviceability, and real-world performance.

Propane-Powered Saws: Built for Outdoor Cutting

EDCO’s SS-20 and SS-24 are designed for outdoor jobs where power, productivity, and mobility are the priority.

- SS-20: Compact but powerful, built for contractors who need to cut trenches, repair pavement, or handle medium-sized jobs with a saw that’s easy to transport and maneuver. Max cutting depth 7 ¾”

- SS-24: Larger frame and cutting capacity for crews that demand maximum output on big slab projects. Max cutting depth 9 ½”

Both propane saws share the same EDCO advantages:

- Heavy-duty 7 & 11 gauge box frames that hold alignment and resist jobsite abuse.

- Easy-access maintenance points for rental centers and busy crews who can’t afford downtime.

- Stable cutting performance that keeps the blade true and reduces operator fatigue.

- Lower emissions than standard gas engines for sensitive areas

For pavement, parking lots, roadwork, or large flatwork in open-air environments, propane models deliver the most productivity without being tied to a power source.

Electric Saws: The Right Choice Indoors

EDCO’s SS-20E and DS-18E are engineered for safe and precise cutting in enclosed environments.

- SS-20E: The electric-powered version of our most popular walk-behind saw. Same rugged design as the propane SS-20 but built for zero-emission work indoors. Max cutting depth 7 ¾”

- DS-18E: A 5HP 230V electric saw for indoor control joints, trenching, and repairs suitable for small spaces, hospitals, schools, and active facilities. Max cutting depth 6 ¾”

Why crews choose EDCO’s electric saws:

- Zero emissions: Safe for use indoors where propane fumes aren’t allowed.

- Quiet operation: Lower noise levels than combustion engines makes them suitable for hospitals, schools, and occupied commercial buildings.

- Consistent design: Contractors and rental customers get the same EDCO durability and parts commonality they trust across our lineup.

What Sets EDCO Saws Apart

Plenty of saws can cut concrete. EDCO’s difference is in how they’re built and supported:

- Serviceable design: All models are built for easy maintenance with many off-the-shelf parts located in the USA and some in stock regionally.

- Proven durability: EDCO frames, arbors, and cutting heads are designed to last in rental fleets and tough field conditions.

- Operator-first engineering: Smooth tracking, simple controls, distributed weight, and clear sightlines reduce operator fatigue and keep cuts accurate.

- American made: Built in the USA with the same reliability that’s defined EDCO equipment for over 65 years.

Matching the Tool to the Job

Choosing between propane and electric isn’t about which one is “better.” It’s about which one works harder in the environment you’re in.

- Outdoor, open-air sites → Propane (SS-20, SS-24).

- Indoor, enclosed, or occupied sites → Electric (SS-20E, DS-18E).

With the right machine matched to the right setting, crews work safer, faster, and more efficiently.

EDCO saws are designed with one goal: to work harder on the jobsite. Whether you choose propane for outdoor power or electric for safe indoor cutting, EDCO gives you durable, serviceable machines that crews and rental customers can count on.