You Asked. We Answered.

EDCO’s Customer-Driven Updates Coming January 2026

At EDCO, innovation doesn’t start in a meeting room, it starts on the jobsite. Every improvement we make begins with conversations with rental partners, contractors, and crews who rely on EDCO equipment every day. You tell us what works, what could work better, and what would make your team more productive. We listen. Then we get to work.

For 65 years, this partnership with our customers has shaped how we design, build, and support our machines. Today, we’re proud to announce a new round of updates inspired directly by your feedback.

TL-9: Customer-Driven Enhancements to a Rental Favorite

The TL-9 has always been known for simplicity and reliability, traits rental customers depend on. This year, EDCO engineers focused specifically on ease of use, operator comfort, and long-term motor protection. Based on direct field input, we’ve made the following updates:

Improved Leveling Handle

A redesigned handle gives operators smoother, more intuitive leveling control, reducing adjustment time and improving grinding consistency.

Easier Handle Folding & Unfolding

We replaced the previous pin design with a new system that makes transitions fast and frustration-free, ideal for rental customers loading and unloading equipment multiple times a day.

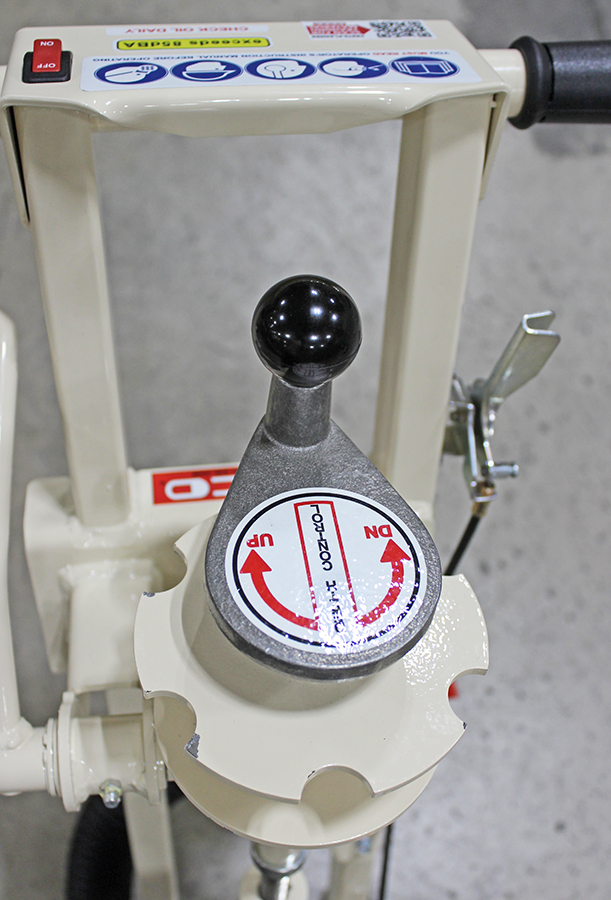

Revised Folding Control

To protect the machine during transport and storage, the folding mechanism was redesigned so the handle can no longer contact the motor when folded.

Smarter Power Management: New Pigtail & 50′ 10-Gauge Cord

One of the most consistent pieces of customer feedback involved power cords and voltage drop affecting the motor. Previously, customers often added extra extension cords to the machine’s already included 25′ 12-gauge cord, unintentionally creating voltage loss that could overload the motor.

We solved this with a complete redesign:

- The machine now features a pigtail connection

- Includes a separate 50′ 10-gauge cord

The heavier gauge significantly reduces voltage drop, and the longer cord eliminates the common need for additional extensions. This update protects the motor, improves performance, and reduces avoidable downtime.

CPM-8: More Comfort, More Control—Standard

The CPM-8 is a workhorse in surface preparation, and your input helped us take its performance and ergonomics even further. Customers asked for enhancements that increase usability for both rental centers and operators. We listened.

Vibration Isolation—Now Standard

The vibration-dampening components used on the UK version of the CPM-8 are now standard across all U.S. models. These isolators reduce the transfer of hand-arm vibration frequencies, supporting operator comfort and extending safe operating time.

Height Adjustment Included on Every Model

What was once an optional feature, the adjustable feather control for use with planing drums, is now included on every CPM-8, regardless of the drum setup purchased. This gives operators precise cutting control right out of the box, making the machine more versatile and rental-ready.

Our Commitment: Continuous Improvement Powered by You

These updates represent more than mechanical upgrades, they’re another chapter in EDCO’s ongoing commitment to supporting rental businesses and the contractors they serve.

- Better usability means faster rentals and fewer questions at the counter.

- Improved durability means more uptime and fewer service headaches.

- Enhanced operator comfort and control means better results on every job.

We’re proud to build American-made equipment that works harder, lasts longer, and reflects the needs of real-world users. And we’ll keep asking for your feedback—because every improvement starts with you.

If you’re a rental partner or contractor who shared insights with us this year, thank you. Your voice directly influenced these improvements, and we can’t wait to show you what’s next.